Thordon Marine Bearings

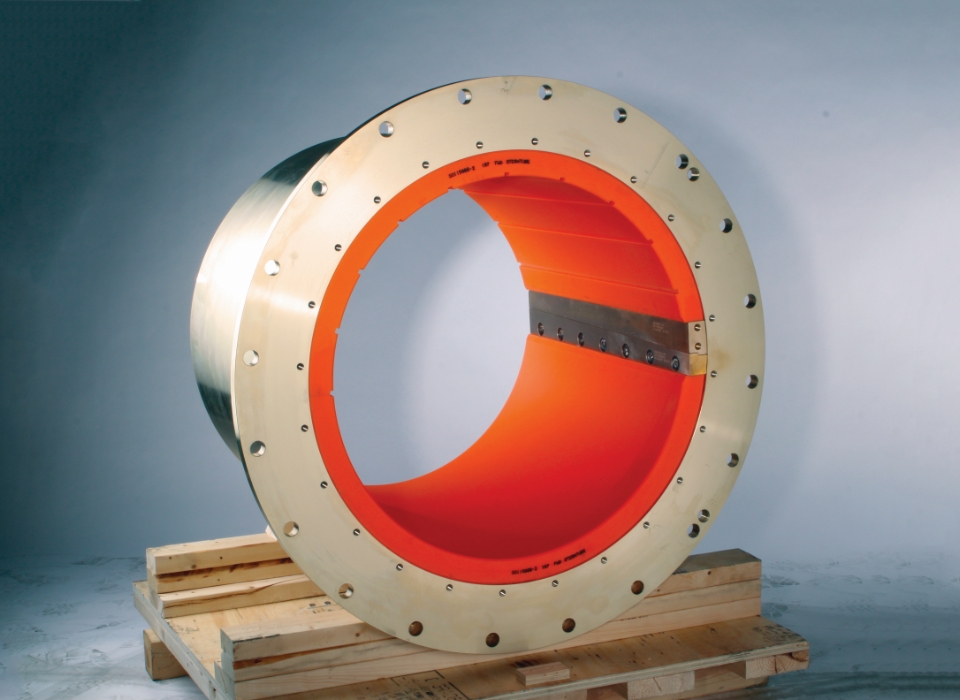

Thordon invented an elastomeric bearing system designed for marine based applications such as water lubricated propeller shaft bearings, rudder system bearings, sealed stern tube bearings, dredge applications, offshore oil applications and deck equipment.

Thordon bearing systems already have over 25 years of marine installations behind them and experience has shown that they are a reliable, pollution free solution for ship owners, managers and shipyards. Thordon systems will meet and exceed the technical requirements and can be applied to all repair, conversion and newly build projects.

At a Glance – The Benefits

- Zero Pollution risk – eliminate grease or oil due to the grease free journal bearings

- High abrasion resistance – operate in dirty abrasive environments with low-bearing abrasive wear rate

- Elastomeric bearing – withstands shock loads and edge loading

- Proven long wear life – lower life cycle costs

- Survivability – non-catastrophic failure mode

- Global availability – technical support and inventory